Committed to progress

On the basis of thorough market observations, in-depth life-cycle assessments and individual feasibility studies, various approaches to the problem, tailored to the specific requirements of your organization and of the sector in which you operate, will be drawn up and presented to you. You will be in a position to recognize any risks at an early stage in the process and to avoid them before embarking on any costly implementation.

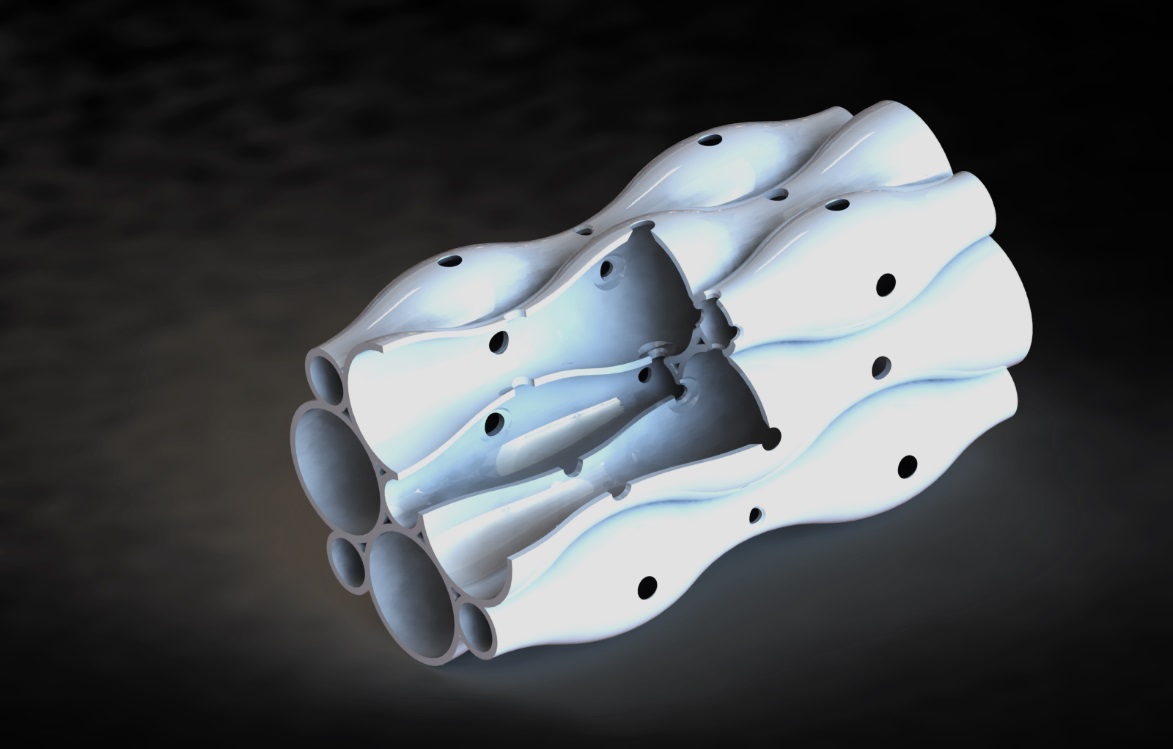

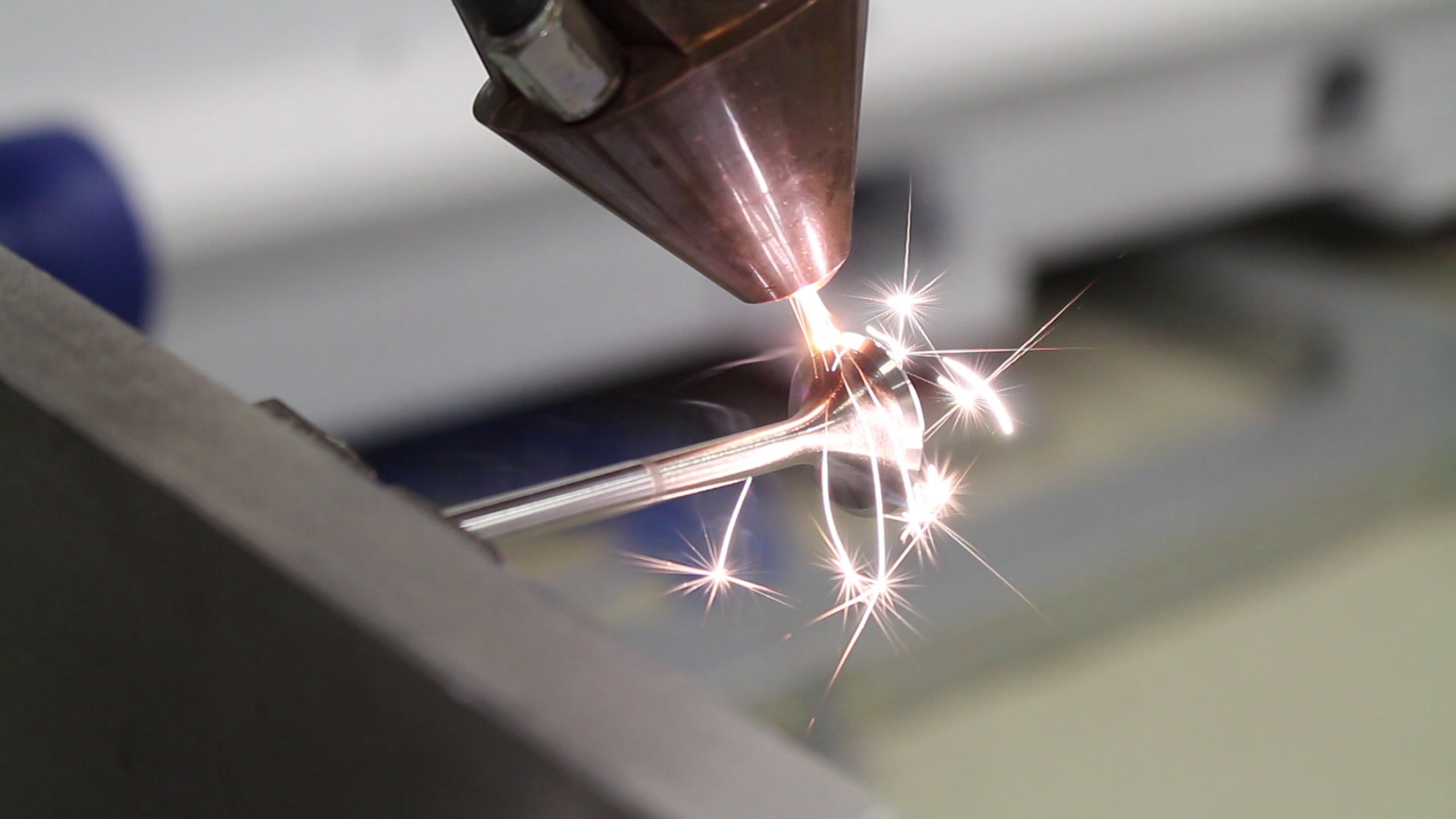

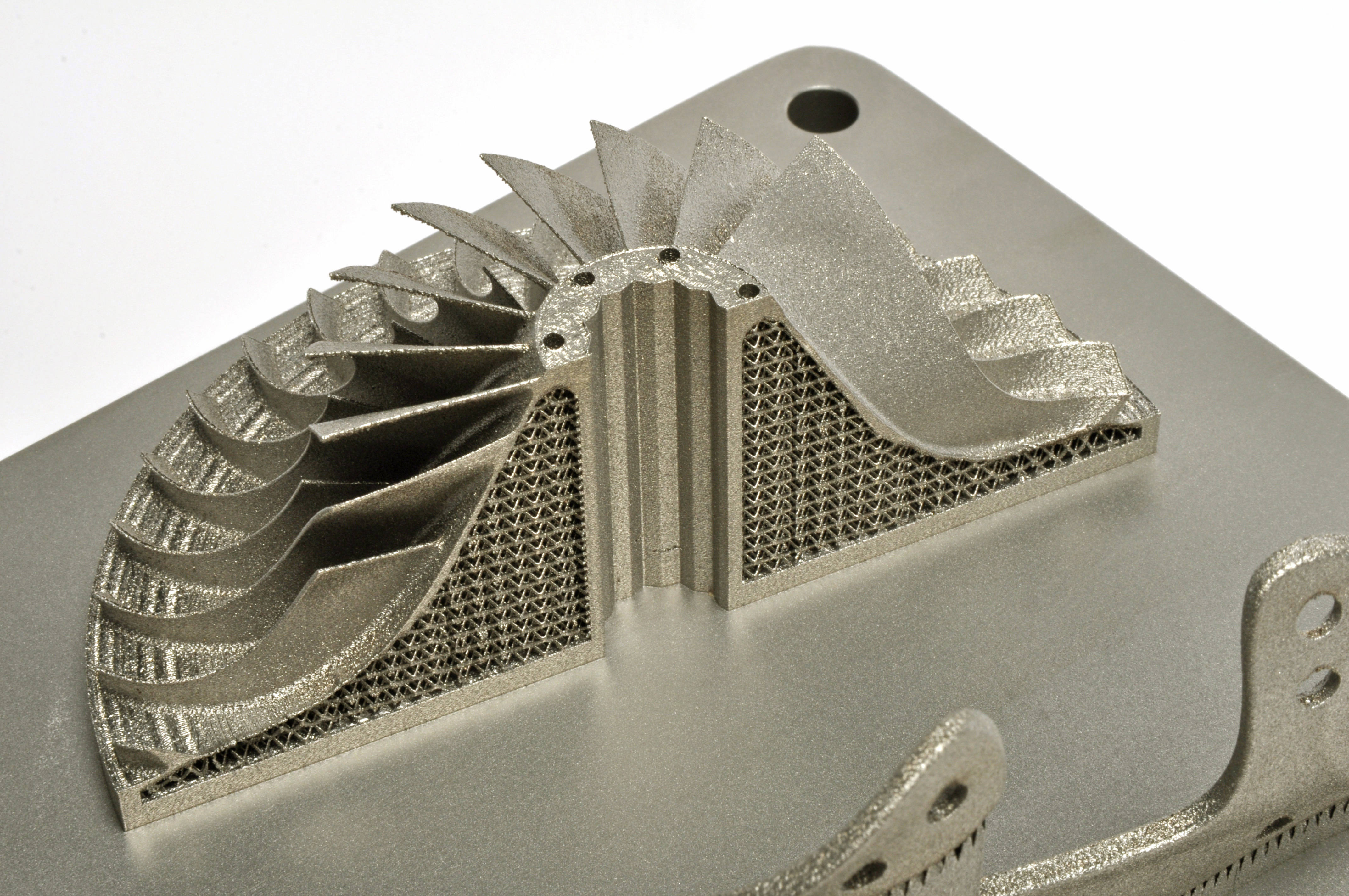

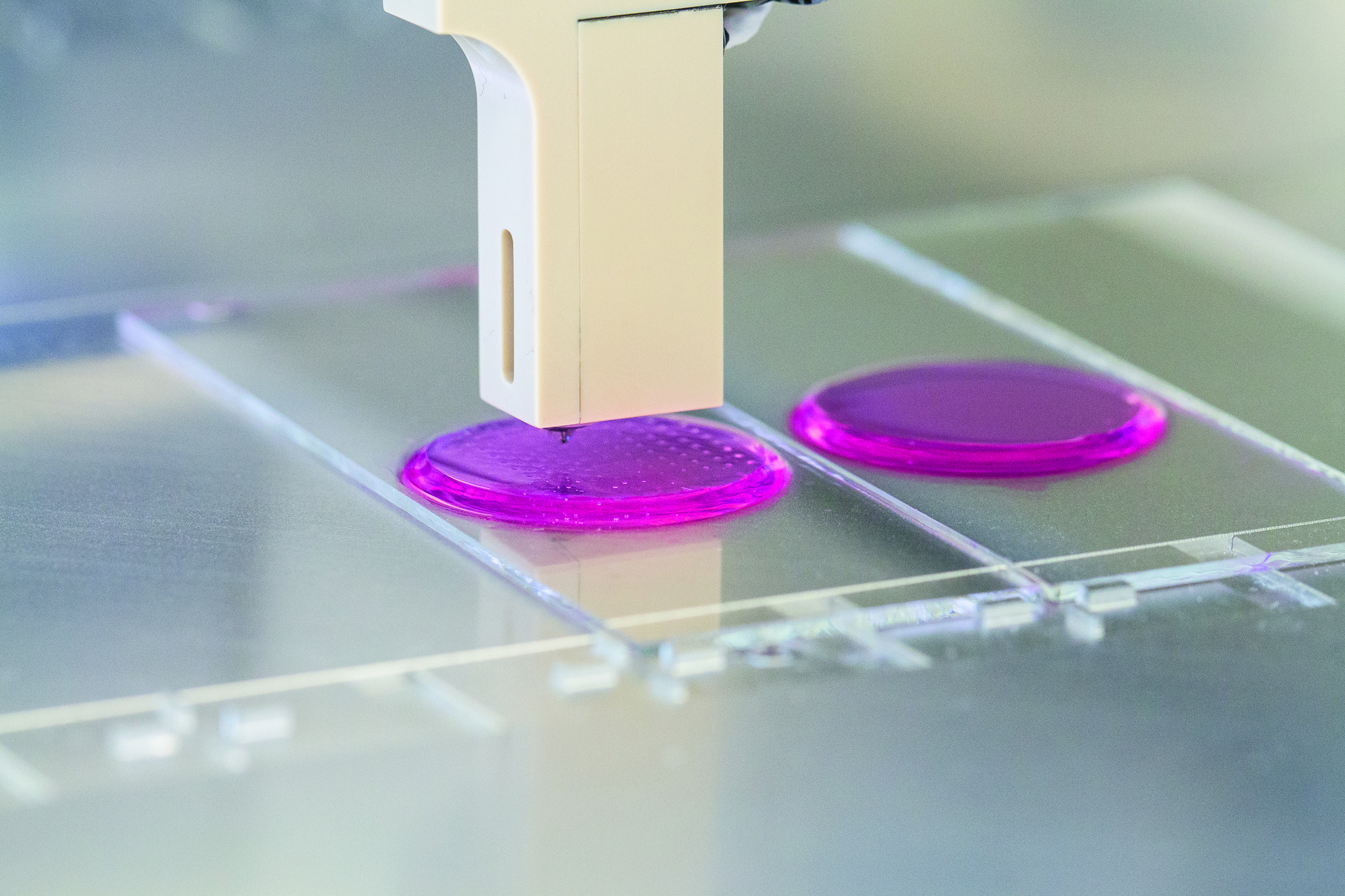

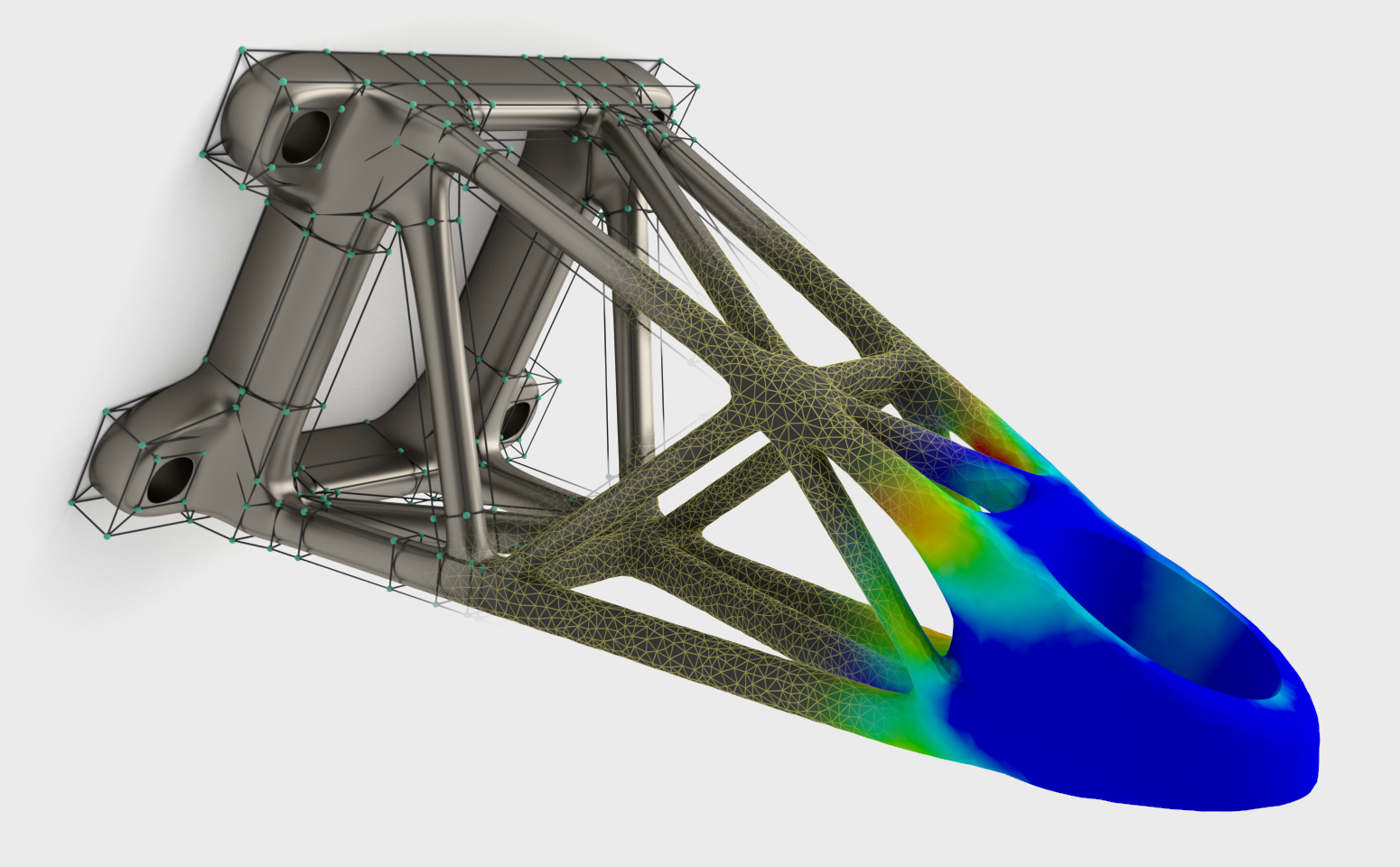

All of the activities undertaken by the Fraunhofer Competence Field Additive Manufacturing revolve around the areas of pivotal importance to us: Engineering, Materials, Technologies and Quality. A diverse range of areas of expertise and numerous development concepts were collated and structured in the run-up to the reorientation of the Competence Field.

Over the past years, our clients have placed their trust in us and have drawn on the following core areas of expertise pursued by the institutes which form the competence field: