Production - from idea to market launch

When developing a product, companies are confronted with rapidly changing markets. For holistic production processes, it is important to analyze precisely all processes and technologies involved in the product lifecycle - from product development to production and logistics. Moreover, production processes have to be optimally synchronized with one another.

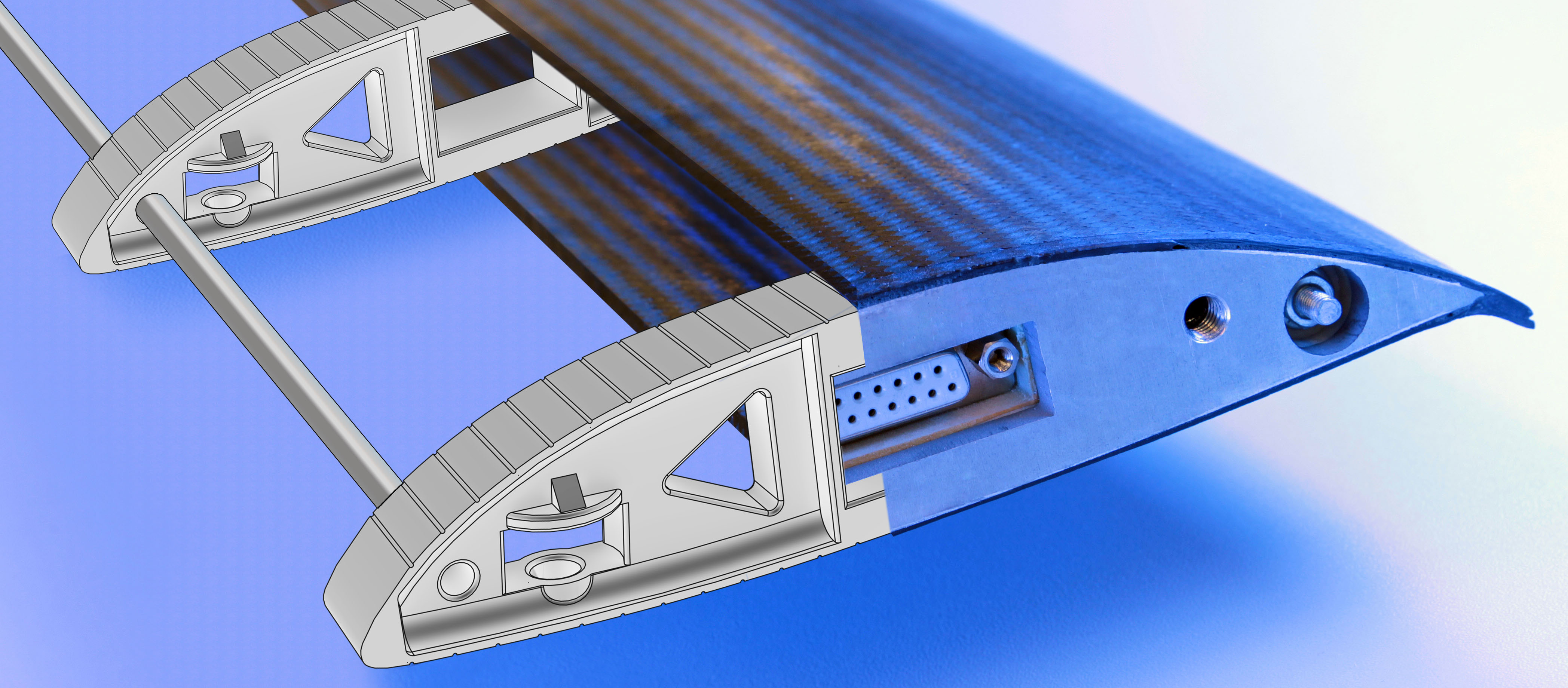

The institutes of the Fraunhofer Competence Field Additive Manufacturing develop new applications by considering all current additive manufacturing technologies. In addition, we offer special systems and comprehensive hardware and software solutions for the following processes:

- Laser-based processes - metals and plastics,

- 3D printing technologies - ceramics and photopolymers as well as

- Process chains and subsequent processes.

The Fraunhofer Competence Field Additive Manufacturing offers you well-engineered and reproducible processes as well as individually adapted systems for your applications and products.