Quality control of powder

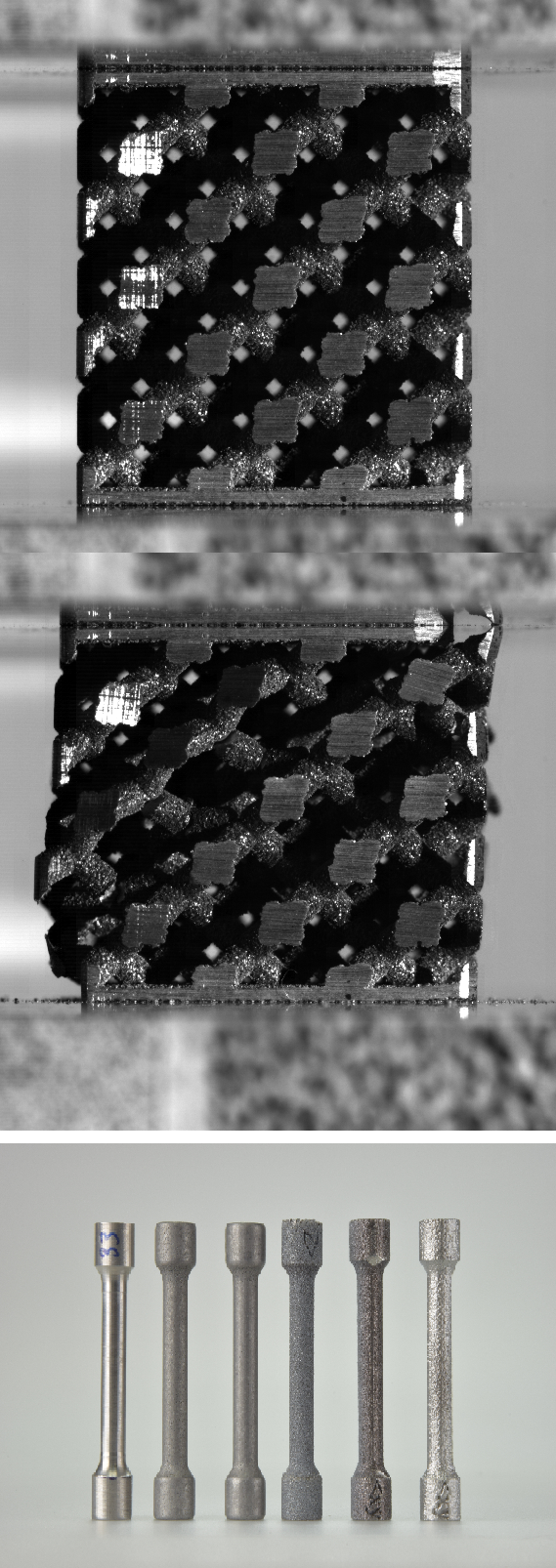

Materials: Ti and Al alloys

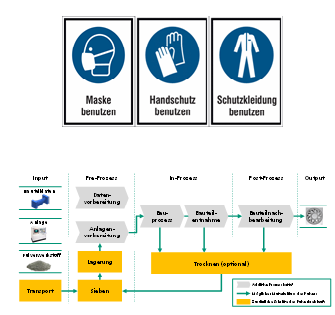

Development of powder specifications for Laser Beam Melting

Development of a quality control strategy for ABM powders

Examination of applicability of new in-line powder testing methods

(i.e.: Revolution Powder Analyser)

Project:

ALM2Air (BMWi LuFo V.2, 20W1501F)

Publication:

Zibelius, Daniela: Vergleich von Analyseansätzen zur Bestimmung der Fließeigenschaften metallischer Pulver für die additive Fertigung von Medizinprodukten. Masterarbeit, Fachbereich 1, Studiengang Medizintechnik, Hochschule Bremerhaven (FH), 2016

Uhlirsch, Markus: Charakterisierung von Aluminium-Legierungspulver für Pulverbett-basierte Additive Manufacturing Prozesse. Bachelorarbeit, Studiengang Oberflächen- und Werkstofftechnik, Hochschule Aalen, 2016

Contact:

Fraunhofer IFAM, Claus Aumund-Kopp, claus.aumund-kopp@ifam.fraunhofer.de