In the research project "EffF3D - Efficient functionalization of 3D-formed thin glass," we are developing a cost-effective process chain for the mass production of functionalized thin glass. This glass is used, for example, in high-quality vehicle interiors such as center consoles, rear-view mirrors and speedometer units.

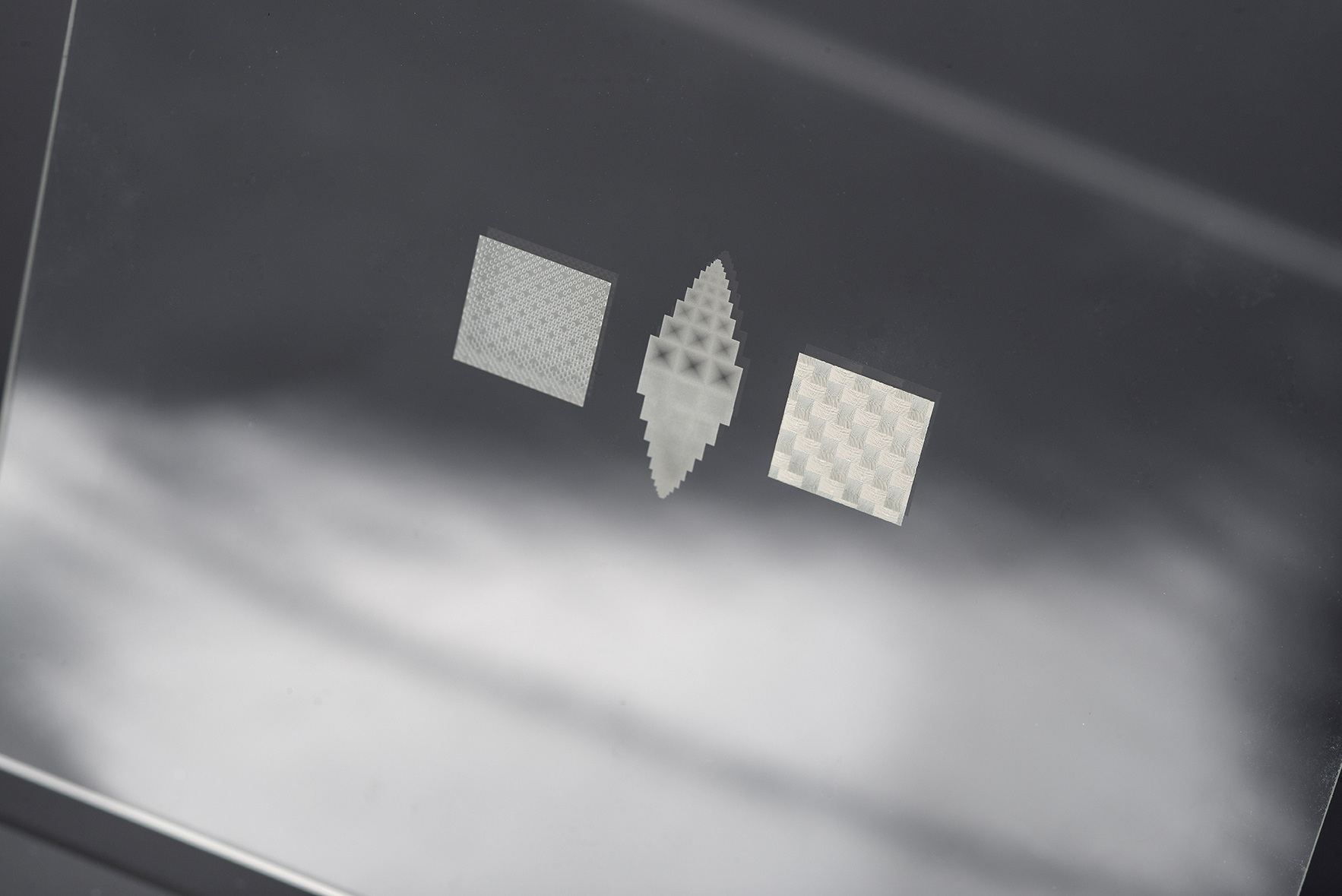

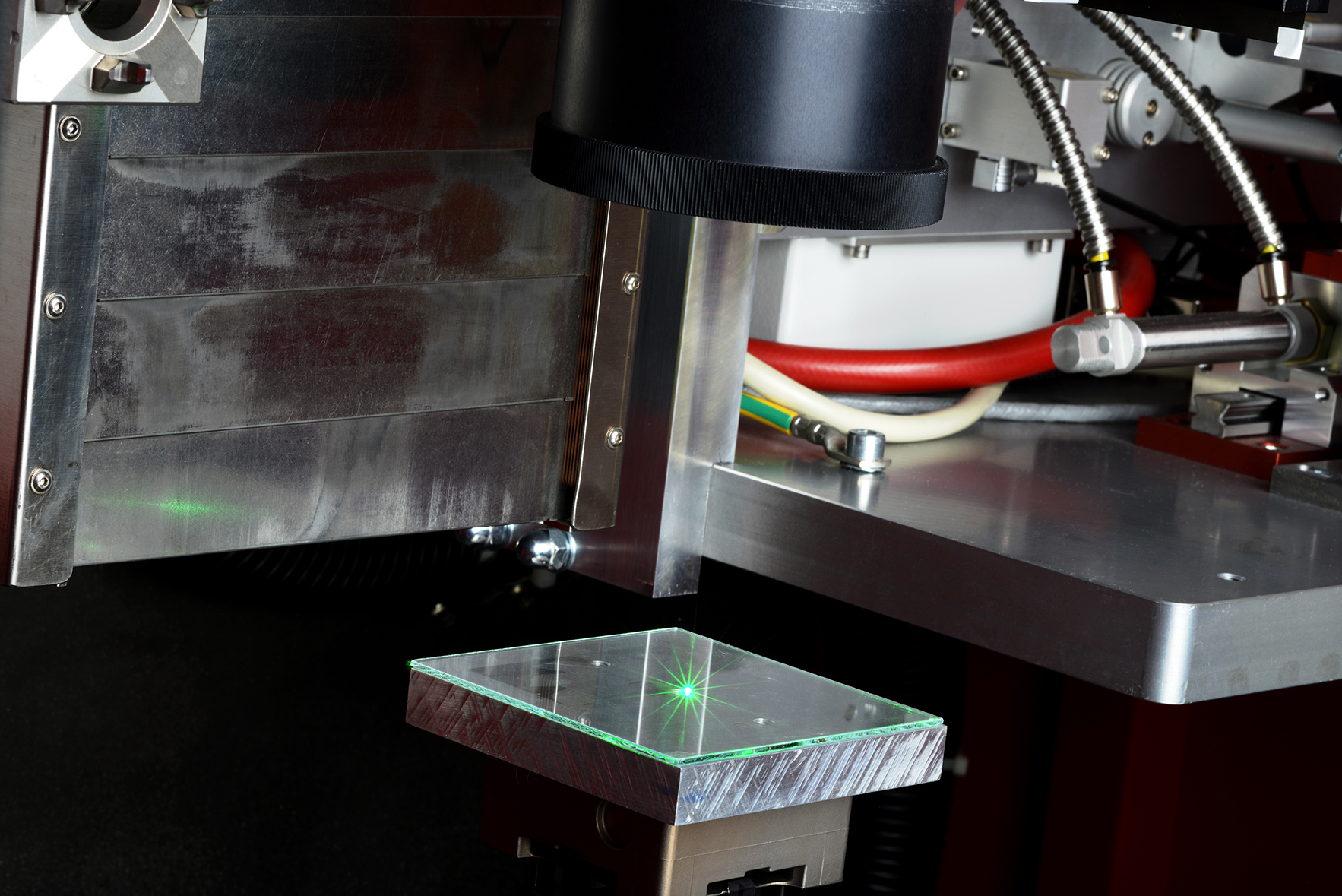

Our innovative process chain is based on two technological pillars: laser structuring of glass blanks and non-isothermal glass forming. When our process is compared to conventional processes, we reduce energy consumption and CO2 emissions by over 60% in each case. We can also completely dispense with the use of harmful chemicals. The new method is also expected to be around 50% cheaper than conventional processes.