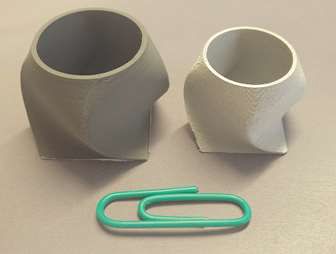

The objective was to develop new manufacturing technologies for optimising inventory in the spare parts business. Of particular interest here were components made of metallic materials that are difficult to manufacture using conventional forming and machining processes. For this purpose, manufacturing concepts based on additive-subtractive generative processes were to be researched and developed, which allow on-site production in line with demand and thus reduce storage, capital commitment and transport costs. The targeted process includes green part shaping by means of fused filament fabrication (FFF) using sinterable filaments containing metal powder, debinding and sintering of the green parts, as well as green part machining, if necessary.

Publication:

Andersen et al “Manufacturing and Properties of Metal Parts Made by Fused Filament Fabrication,” -1, 2018. https://publica.fraunhofer.de/handle/publica/402534.

Contact:

Fraunhofer IFAM, Dr.-Ing. Sebastian Riecker, sebastian.riecker@ifam-dd.fraunhofer.de, +49 351 2537 429