The material palette available for additive manufacturing is expanding rapidly. However, it has not yet been possible to process foamed materials in additive processes, although this would be extremely interesting for example in the field of functional lightweight construction. If it were also possible to locally change the density of the foam material, extremely light structures optimised for the specific loads could be produced. Against this background, materials and additive processing technologies for the production of rigid foam structures were developed in the joint project "bioXXprint - A printer for bio-based foam structures". The project consortium included Fraunhofer IPA, Fraunhofer ICT and the Institute of Wood Technology Dresden. The application on which the project is based, the individualised manufacture of upholstered furniture, was represented in the project by the company Rolf Benz as an associated partner.

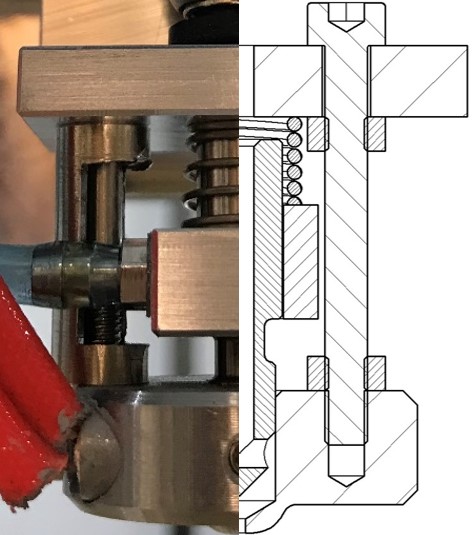

The task of Fraunhofer IPA was to develop a process technology suitable for processing foaming materials. Due to the propellant content of the filament, there is an unwanted outflow from the nozzle during position or layer changes of the print head without active filament feed. This results in a significant reduction in component quality, increased material consumption and the need for post-processing steps. To overcome this, a new type of nozzle with a hollow needle valve was developed. This mechanism, which has been applied for a patent, has a passive mechanism which closes the nozzle opening when the filament feed stops and prevents the plastic melt from leaking out. By varying the pressure parameters, the foaming behaviour can be influenced so that the density of the component can be adjusted location-selectively.

Thus, an extrusion-based, additive manufacturing process was implemented which enables the processing of thermoplastic foams. Further development is planned and it is currently being investigated which benefits the developed extrusion mechanism has in the processing of other materials: on this basis, improvements could be achieved in the processing of thermoplastic materials with very low melt viscosity.

Project:

bioXXprint - A printer for bio-based foam structures

Link:

Contact:

Fraunhofer IPA, M.Sc. Jonas Fischer, jonas.fischer@ipa.fraunhofer.de, +49 711 970-1119